Not just an ordinary gathering, but a pivotal moment for the strategic future of the…

The launch of a research project to improve the energy efficiency of production processes, reduce atmospheric emissions, and transform production with a circular economy approach; attention to employees through new locker rooms and offices; exceeding the target of 30 training hours per employee; initiating partnerships with local technical schools for work-study programs; and numerous social initiatives benefiting local communities. These are just some of the achievements outlined in Altair Chemical’s second Sustainability Report for 2023, a year that concluded with the successful merger of the Pieve Vergonte (VB) and Saline di Volterra (PI) plants, aimed at enhancing competitiveness in the market.

“The development and strengthening of Esseco Industrial’s chlor-alkali division are reflected in the milestones highlighted in this second Sustainability Report. This progress stems from a journey of production renewal, capacity building, and environmental focus supported by significant ongoing investments,” explains Roberto Vagheggi, General Manager of Esseco Industrial and CEO of Altair Chemical. “At the same time, we maintain a strong commitment to the regions hosting our production sites. In 2023, at Saline di Volterra, we contributed €1.6 million through the Sports Bonus to start construction of the stadium, donated a small playground to a nursery school, and at Pieve Vergonte, we established a cafeteria open to the community, alongside philanthropic donations to cultural, sports, and social organizations.”

Altair Chemical’s environmental, economic, and social sustainability efforts have also been recognized with certifications and awards, including the prestigious EcoVadis Gold Medal for the third consecutive year—a distinction achieved by only 5% of assessed companies. “Innovation geared toward sustainability continues through research and development projects,” adds Vagheggi. “In 2023, we successfully completed the Ministry of Enterprises’ first assessment of the Re-Born project. This initiative revitalized the Pieve Vergonte plant acquired in 2019, encompassing studies of new processes, environmentally sustainable technological solutions for industrial chlor-alkali production, and the development of innovative procedures and alternative productions.”

Several examples illustrate the integration of circular economy principles into production processes. Carbon dioxide from cogeneration is used to produce potassium carbonate; condensate water from processes is recycled into other production activities as demineralized water; and hydrogen generated by salt electrolysis is repurposed as an energy source, replacing methane to fuel a steam-generating boiler. A standout example of circular economy in action is ferric chloride, produced by utilizing waste acid from steel processing.

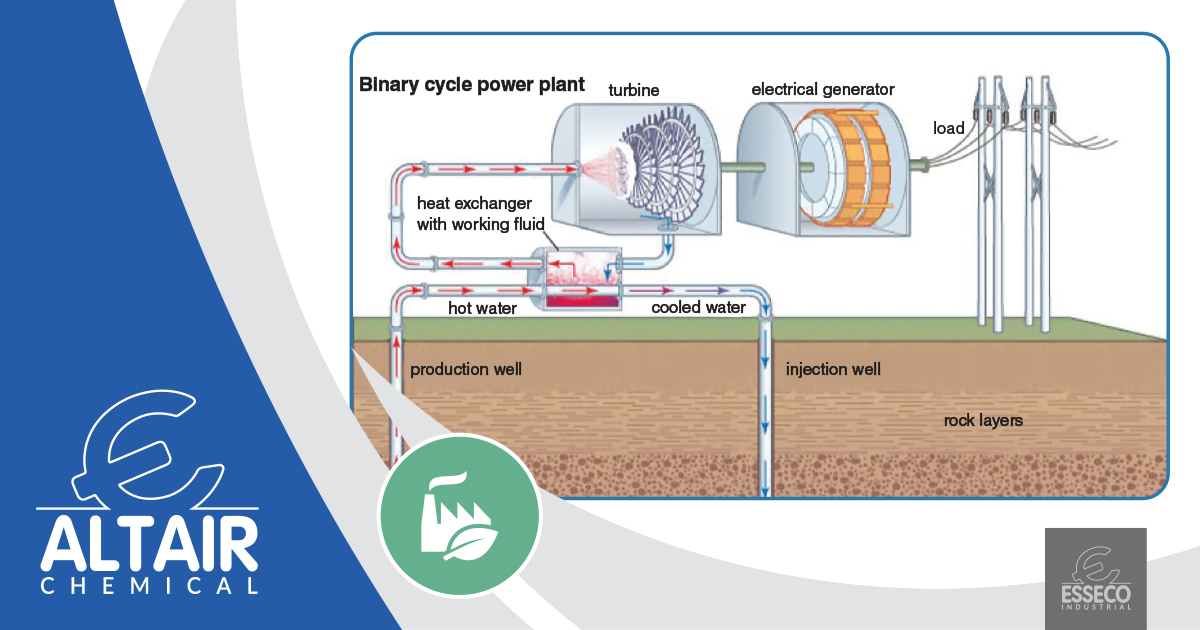

“On the energy front,” concludes the CEO of Altair Chemical, “new investments in photovoltaic systems and hydroelectric plants in Piedmont have increased the share of renewable energy utilized and self-produced electricity. In 2023, we made a significant €11 million investment in off-site photovoltaic systems to further expand our use of renewable electricity in the coming years. Additionally, in Tuscany, we conducted a feasibility study on the geothermal potential near our plant, which could serve as a foundation for future developments, supported by the openness and dialogue with local institutions.”

Finally, agreements were signed with the Commercial and Technical Institute for Surveyors in Volterra and technical schools in Verbania and Domodossola to develop work-based learning and orientation programs (PCTO) for young students.