The first 100% electric journey between two Esseco Industrial sites has officially taken place: 25,500…

The energy crisis triggered by the post-pandemic recovery has made achieving greater energy efficiency even more urgent for the highly energy-intensive chemical industry. Esseco Industrial has been at the forefront of this through various research and development projects in collaboration with selected university departments and accredited research centers.

To analyze and spread best practices and projects, Federchimica-Confindustria is celebrating the “Day of Chemical Research” today, September 28, in Milan, dedicating it to “Innovation at the Service of Energy.” Businesses, universities, and research centers are discussing innovations in energy for the chemical sector. Researchers have long been working on accumulative and distributive efficiency, new materials and solutions, hydrogen as a new vector, and general decarbonization, playing a fundamental role in the decarbonization goals for 2050. The focus of the day includes electrolysis, high-performance batteries, and biofuels.

Let’s delve into the details of the R&D projects currently underway or already concluded at Esseco Industrial companies.

After historically using the significant heat emission from the production of sulfur dioxide from sulfur to produce high-pressure steam and provide energy for the entire facility, at Esseco Srl we invested 40 million euros to renew the sodium hydrosulfite (SHS) production plant, which allowed us to reduce wastewater disposal costs, making the entire process more efficient. With a methane-powered trigeneration power plant, we supply steam to the facility and channel the cold water, reducing electrical consumption. Additionally, just a few days ago, we applied for a grant from the Piedmont Region for a new efficiency project. By halving the temperature of the gases exiting the sulfur combustion furnace—from 300° to 150° C—we will recover additional steam that, through a new turbine, will produce 1,600 MWh of additional energy. Our significant focus on water resources also prompted us to consider a solution to reduce well water extraction. By introducing a refrigeration unit combined with a pre-cooling air cooler, we will reduce the water consumption of the modified plant by about 90%, thus contributing to environmental and economic sustainability.

At Altair Chimica, to maximize the energy value of hydrogen from the industrial process, we previously researched and installed a prototype bi-fuel steam generator and later initiated a research study with UNIFI REASE that led to the installation of a new boiler. With full hydrogen technology for steam production, this allowed us to reduce methane consumption significantly. This was complemented by an R&D project with the Institute of Geosciences and Georesources in Florence aimed at identifying the most energy-efficient and environmentally sustainable method of self-generating electricity for our company: from this, the photovoltaic plants installed at the facility emerged, and the groundwork was laid for future geothermal research. Pursuing the ambitious path of renewable energies, we then signed the first Power Purchasing Agreement (PPA) and decided to make significant investments in extra-site solar energy.

The collaboration with ICCOM-CNR and the Engineering Department of the University of Florence resulted in a 14 million euro investment for a new electrolysis line, increasing the plant’s productivity by 50% and enhancing electrical performance.

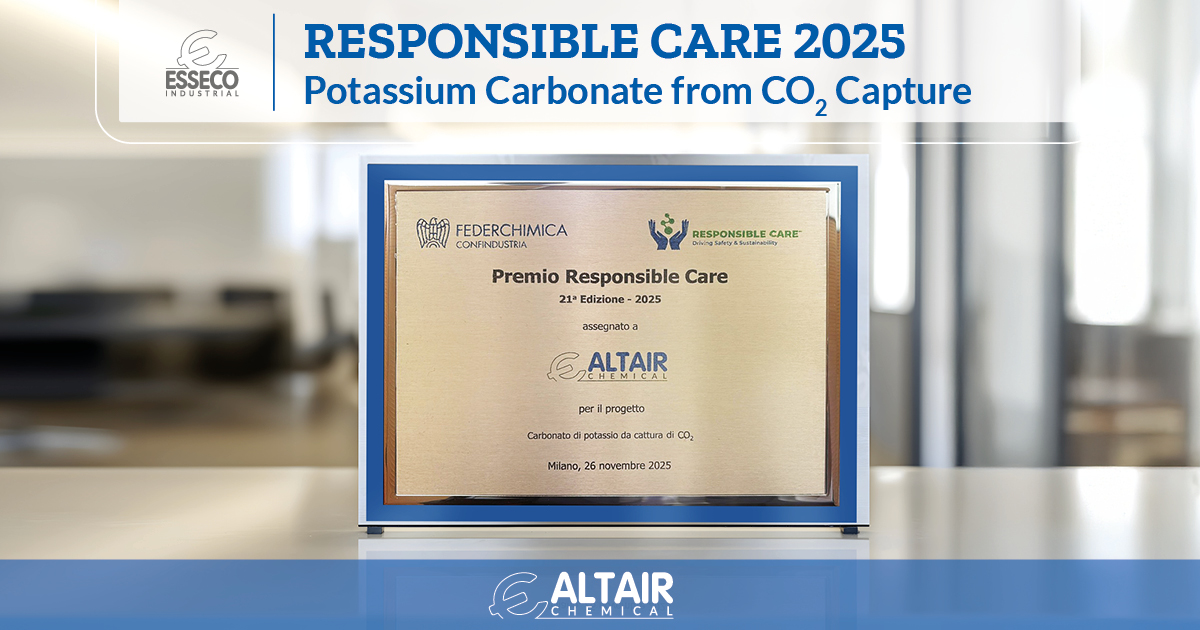

In terms of greenhouse gas emissions control and CO2 capture and reuse, the company’s most significant investment involved the installation of a CO2 and heat recovery plant from the fumes of the high-efficiency cogeneration of 4.6 MWe, aimed at producing potassium carbonate (K2CO3). This project for capturing and using CO2 from the fumes for carbonate production has allowed us to partially reduce the emissions of the cogenerator itself. We are continuing on the path of this successful project, planning to achieve a similar recovery from the fumes of the newly installed cogenerator, with a goal of increasing CO2 capture by 50%.

At Hydrochem, with an ambitious industrial relaunch project underway since the acquisition of the facility in 2019, we installed a new membrane electrolysis process that falls within the BAT (Best Available Technologies) in Europe, introducing new developments capable of surpassing the state of the art previously achieved internationally and by the group. We have also found plant solutions to ensure the highest possible flexibility of production loads: in this way, we make the best use of the energy from the two hydroelectric plants serving the facility and reduce network energy absorption.

New projects will soon be underway for further innovations in energy, thanks to collaboration with universities and accredited research centers. R&D will support Esseco Industrial’s ambitious path toward reducing emissions related to its electric needs: to date, we have already achieved 50% renewable energy.